|

|

Unlike conductors, insulators do not allow the flow of electricity. Therefore, static electricity cannot be removed from insulators

the same way it can from conductors. Three methods are primarily used to remove static charges from insulators.

Anti-static agents can be sprayed onto the surface of insulators to create a conductive film that prevents the insulator from becoming electrically charged.

While this is an easy solution, the film does not last very long, requiring frequent spraying.

An alternative method is to mix conductive elements,

such as carbon or metal particles, directly in the raw material for the insulator.

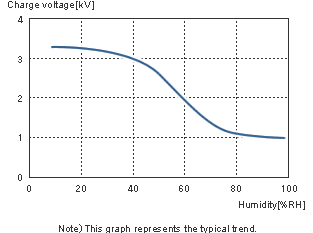

Typically, static electricity occurs more in the winter than it does in the summer.

This is due largely to the effects of ambient humidity.

Higher humidity causes greater moisture on the surface of the insulator.

Water is conductive and forms a film on the surface of the insulator. This, in turn, reduces the resistance of the insulator and results in a decreased electrical charge.

While conductivity and humidity control can be effective for removing a static charge from insulators, the effect is not permanent and may be costly. Also, these methods may not be possible for some materials. An effective solution to these shortcomings is the use of a static eliminator.

Static eliminators can eliminate static electricity by neutralizing targets with positive and negative ions.

Unlike conductivity measures, static eliminators are easily installed into existing areas and offer long-term effectiveness at a low cost.

It also has a smaller footprint than humidity control equipment, making it much more efficient and economical to implement.