Laser Profiler

Laser profilers are laser displacement sensors that collect height data across a laser line rather than a single point. This enables 2D/3D measurements such as height difference, width, or angle to be performed using a single sensor. In addition to height data, KEYENCE profile sensors also collect intensity data to provide a stable solution for inline measurement and inspection. The lineup includes a wide range of sensors to support a variety of applications and industries.

Recommended Items

Products Lineup

Perform 2D/3D measurement and inspection in line with the LJ-X8000 Series. Our most versatile lineup of laser profilers offers 3200 points/profile, making it easy to accurately measure any target shape or material from high-resolution images. The laser profile scanners are compatible with four different controller options, allowing users to select a setup that perfectly aligns system capability with any application requirements. The maximum laser linewidth reaches over 720mm (28"), and multiple can be paired together to scan even larger targets. Programming for these high-performance sensors is completed in three simple steps, making accurate in line 3D measurement accessible for users of any experience level.

Features

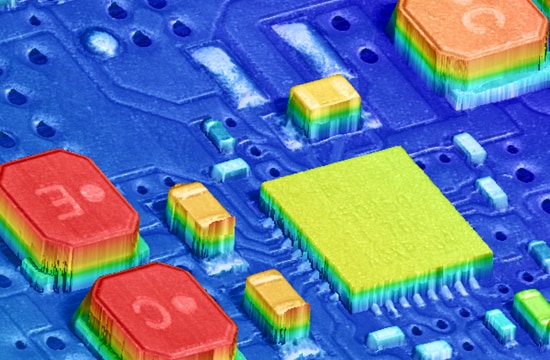

Improve Reliability with 4x More Resolution

Capturing the true shape of a target is critical for performing reliable inspections. With 3200 points/profile, the LJ-X8000 Series captures target shape in high resolution, enabling accurate inline measurement.

Conventional

- Rough

- Irregular

- Surface dependent

LJ-X8000

- Detailed

- Consistent

- Stable on any surface

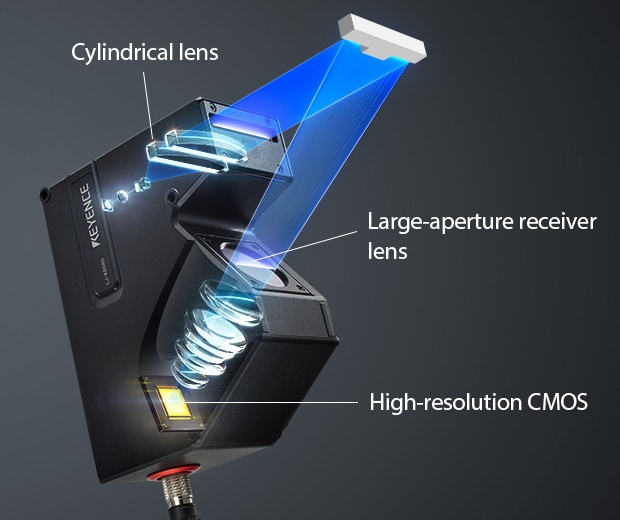

Maximising Resolution and Target Detection

To improve the resolution of the sensor, the number of pixels on the CMOS needs to be increased. This can be accomplished by making each pixel smaller; however, smaller pixels can result in insufficient light detection, causing an inaccurate profile on some targets. For the LJ-X8000 Series, we’ve implemented new technology to create a laser profiler capable of high-resolution measurement on any target.

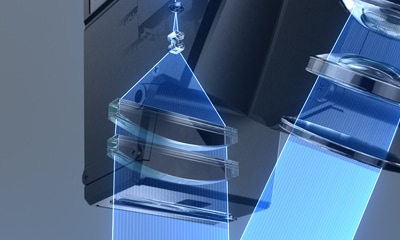

Cylindrical lens

Parallel light is emitted using a cylindrical lens designed to prevent the reflected light from scattering across the surface of the target. This ensures reliable reflections from any shape or surface.

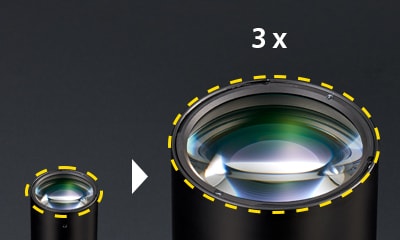

Large-aperture receiver lens

The sensor is equipped with a receiver lens that has 3x more area than conventional models, increasing the received light intensity. This allows the sensor to produce stable profiles in any environment.

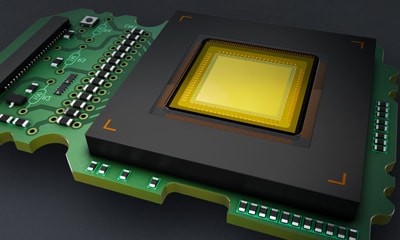

High-resolution CMOS

This newly developed CMOS enables high-resolution measurement using 3200 points/profile, while delivering improved imaging capability on targets with varying reflectivity.

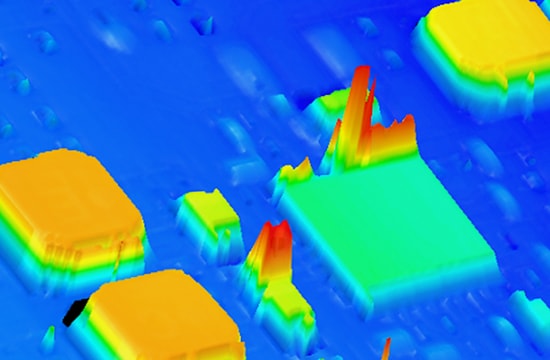

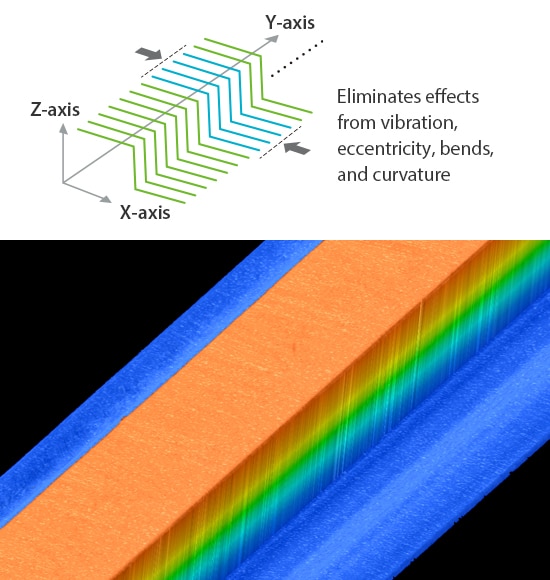

Profile Alignment Function

When creating a 3D image, the positions of each 2D profile are adjusted in the X, Z, and θ directions. This eliminates the impact of vibration and eccentricity as well as bends and curvature in the target, creating an optimal image for inspection.

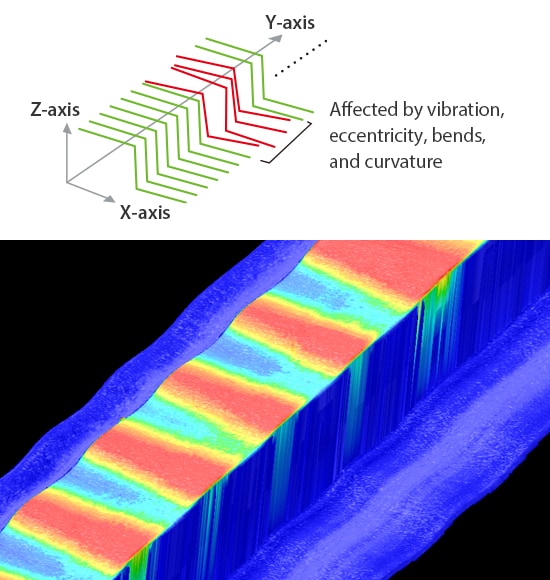

Without profile alignment

Without profile alignment, the target image is distorted by vibration, making it impossible to perform accurate inspection.

With profile alignment

Profile alignment allows for an optimal 3D image to be created. This achieves stable, inline inspections for dents, chips, and other defects.

THE WORLD’S FASTEST AT 64,000 PROFILES/SEC. Speed that makes the measurement of any product and of any shape a reality!

The LJ-G Series accurately measures the surface profile of targets in X and Z directions. The height, width or gap on a surface profile can be measured using 28 measurement modes.