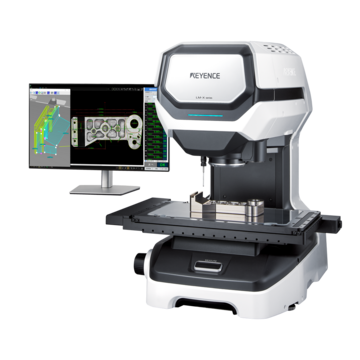

Multisensor Measurement System

LM-X series

Multisensor Measurement System LM-X series

High-Precision Optical, Laser, and Probe Measurement System

Taking "place-and-press measurement" to the next level.

- High-accuracy submicron measurement / High-speed, high-accuracy measurement

- Measure up to 5000 locations on up to 1000 parts

- Inspect parts with a wide-range of shape, size and material

High-accuracy (±0.1 µm) measurement can be performed easily just by placing the part on the stage and pressing a button. Three measurement methods are available: high-accuracy image measurement, non-contact height measurement via a multi-colour laser, and contact measurement via a 3D touch probe. This product drastically reduces the dimensional measurement time of complex parts and ensures accurate measurements with no variations between results obtained by different operators.

Features

No Time-consuming Positioning or Coordinate Creation Required

The location and orientation of parts placed on the stage are automatically detected. This eliminates the need for conventional labour-intensive positioning, creating coordinates, and preparing fixing jigs.

-

1STEP1 : Place

-

2STEP2 : Press

-

3STEP3 : Obtain results

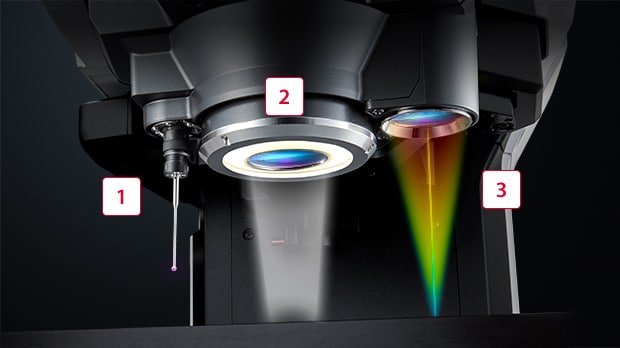

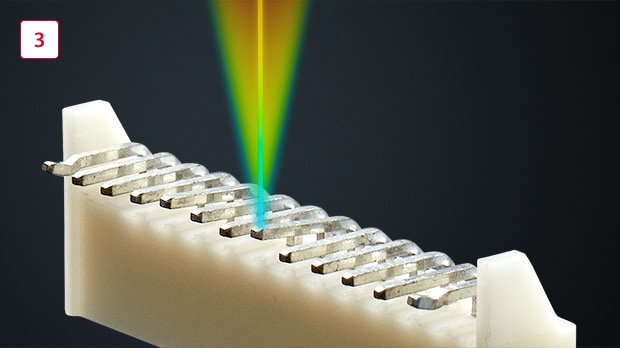

Three Different Measurement Methods for Fast and Easy High-accuracy Measurement

Highly-accurate measurement along the X, Y, and Z axes.

-

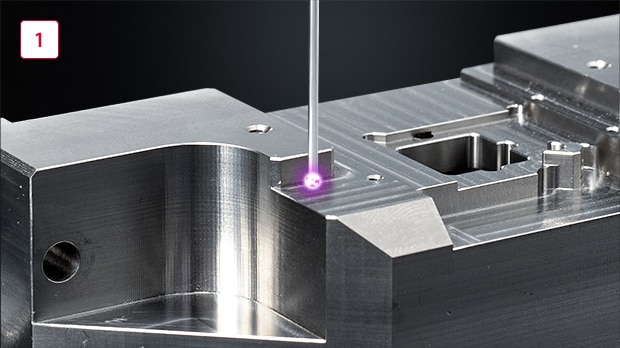

1Touch probe : measurement of three-dimensional parts

-

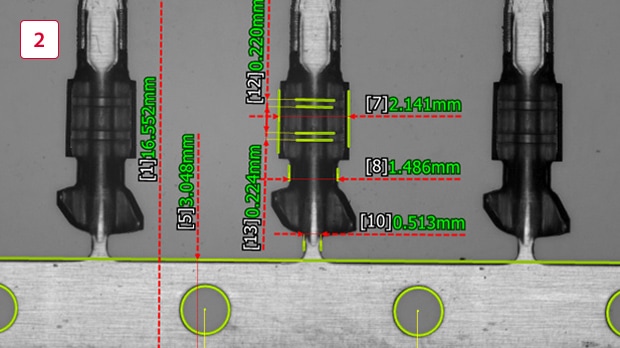

2Ultra-high-resolution camera : High-accuracy image measurement

-

3Multi-colour laser : Instant height measurement

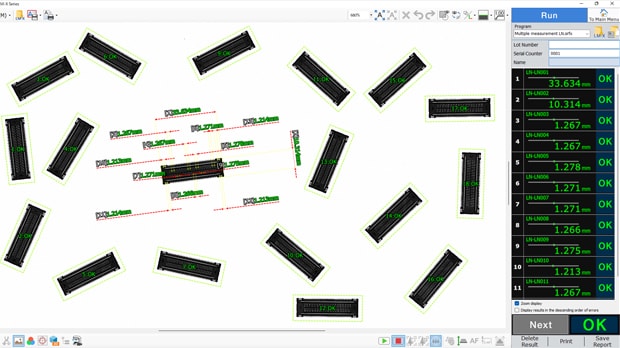

Measure up to 5000 Locations on up to 1000 Parts

Fast, simultaneous measurement is possible even when multiple parts are placed on the stage. There is also no need to use fixing jigs.

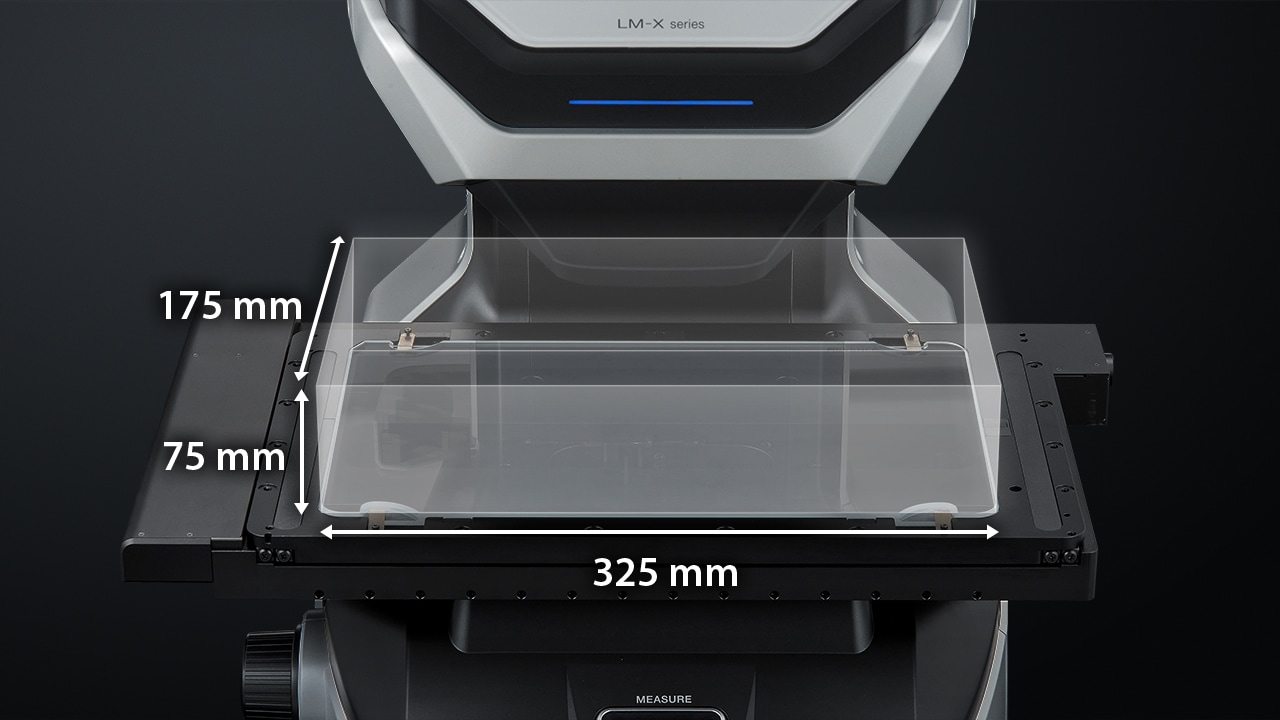

Large Low-Vibration Stage for High-Speed Measurement

The large stage has a maximum measuring area of 175 × 325 mm and a working height of 75 mm. The new design reduces the friction between the motor and feed screws as much as possible, allowing for quick and stable measurement without fixing the part in place.